- DISCOVER

- TECH SPECS

- CAD FILES

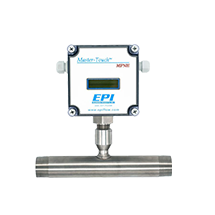

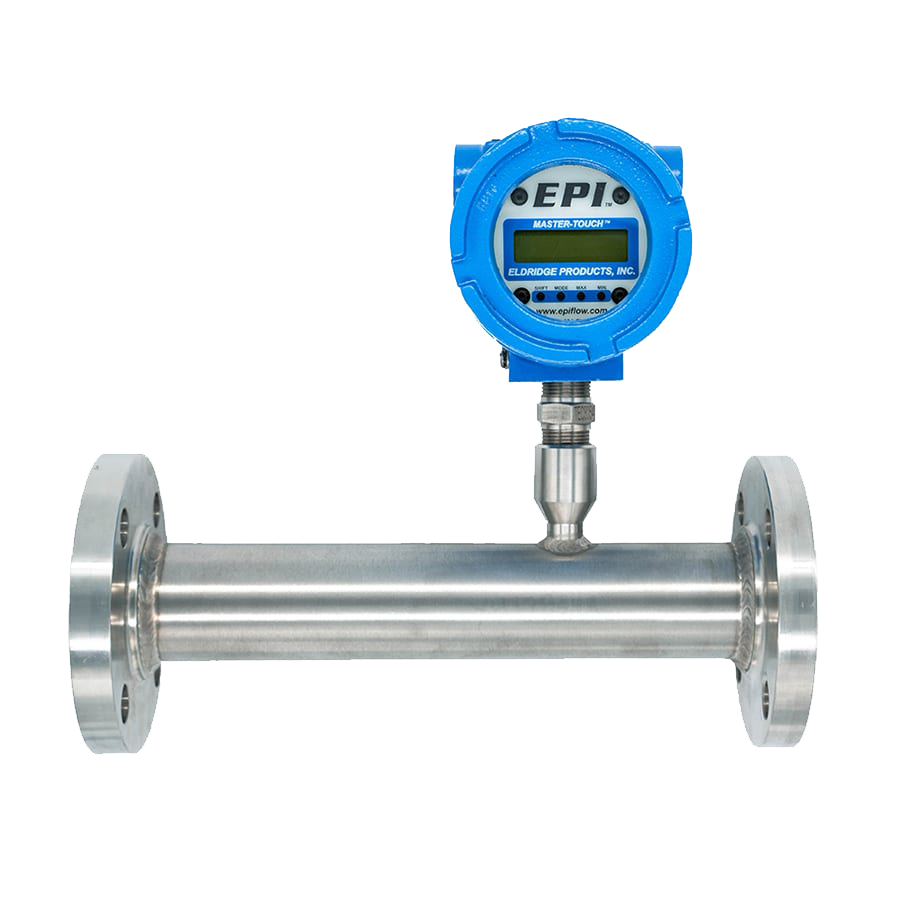

Master-Touch™ Series 9700MP HAZ FAT Inline Flow Meters

Flawless for usage in hazardous areas, the Master-Touch™ Series 9700MP thermal mass flow meters are an indispensable piece of equipment to provide you with precise and dependable thermal monitoring.

Offering an Inline style thermal mass flow design that features the sensing elements openly mounted on the flow suction, the Inline style of the Series 9700MP Flow Meter is available in sizes from 2” pipe through to 4” pipe and can be provided with flanged end arrangements if necessary.

The Series 9700MP is offered in an Integral Style that makes readings exceedingly simple by providing all the electrical apparatuses and mechanisms in a centralized location in an enclosure. A simple yet refined system, the Series 9700MP is an essential piece of engineering.

- Inline and Integral style that provides efficiency and reliability

- Rated for hazardous environments

- Includes EPI’s renowned and patented Flow Average Tubes

- Custom options available via the Customizer

METER TYPE

Inline

Inline

ENCLOSURE

Integrated Electronics

Integrated Electronics

WARRANTY

1-4 Years

1-4 Years

CERTIFICATIONS

CE, CSA/CUS, IECEx, KOSHA, ATEX

CE, CSA/CUS, IECEx, KOSHA, ATEX

Product Description

Master-Touch™ products include a rugged, cleanable, thermal mass flow sensor. These units consist of a sensor assembly which utilizes two RTD (Resistance Temperature Detector) sensing elements. The sensors are constructed of reference grade platinum, ceramic, glass, and stainless steel. Two platinum resistance sensors are built up upon the ceramic substrate and then given a thin glass coating. The assembly is then slipped into a stainless-steel sheath for corrosion and abrasion resistance. The sensor assembly is large, rugged, and relatively insensitive to dirt buildup. During operation, the temperature sensor constantly measures the ambient temperature of the gas and maintains a reference resistance on one side of a bridge circuit. The second sensor is forced through self-heating to a constant temperature above that of the gas stream and is controlled by the temperature sensor and bridge circuitry. Our bridge maintains the overheat temperature and counterbalances the temperature effects through our proprietary temperature compensation techniques.

9700 Series flow meters are approved for use in hazardous locations (see specifications).

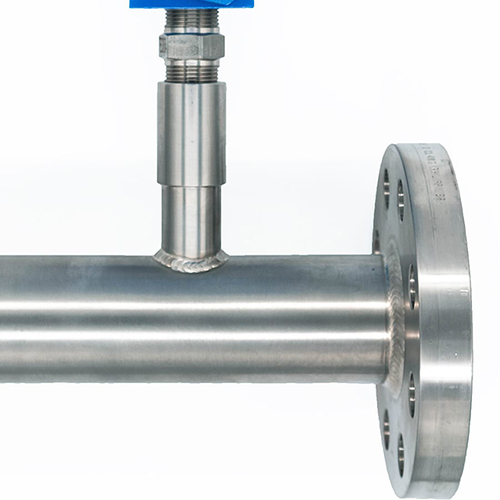

Inline style thermal mass flow meters include a flow section that is usually specified to match the user’s flow conduit and is then plumbed directly into the process line. This design has the sensing elements mounted directly in the flow section for exposure to the process gas. Our inline style thermal mass flow meters are available in sizes from 1/4″ pipe through 4″ pipe or tube and are provided with a variety of options such as MNPT ends, tube end fittings, butt weld ends, flanged end configurations, etc. as required. Pipe sizes more than 4″ typically require insertion style thermal mass flow meters.

Integral style thermal mass flow meters have all the electrical components and connections located within one enclosure. This enclosure is rated for hazardous environments. The enclosure is mounted directly to the inline flow section at the point of measurement. The enclosure includes all the electrical connections as well as the linearizing electronics and the display/keypad assembly.

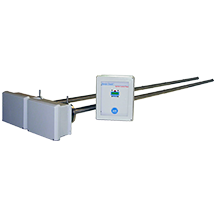

Our patented Flow Averaging Tubes™ (FAT™) use the principle of convective heat transfer to directly measure mass flow and are well suited to most applications with limited available straight run. In many installations, the up-stream straight run can be reduced to three diameters. The probe has several large diameter inlet ports along the length of the upstream impact surface. The pressure at each inlet port is averaged inside the tube to create the axial flow through the tube and across our flow sensor. The gas returns to the main flow stream through the ports located near the sensing elements. Anomalies in the actual flow profile or installations in non-circular ducts may still some require minor adjustment to achieve the best accuracy.