Oxygen Gas Measurement with Thermal Mass Flow Meters

Uncompressed air and oxygen gas are used in a wide variety of commercial and industrial applications, covering everything from steel production to dehydrating fruit to renewing municipal water supplies. Uncompressed atmospheric air is chosen for many applications for obvious reasons – it’s plentiful and effectively free. Pure oxygen is more costly, but its chemical properties make it an important input in many industrial processes where minimizing fuel waste and catalyzing chemical reactions and biological processes are the goal. In all cases, the key to ensuring efficient production and minimized costs is the careful measurement of the input gas – a task that can be made more accurate, more repeatable, and more cost-effective with the right technology.

Industrial Combustion

The importance of combustion to industry can’t be overstated, with furnaces, boilers, and heaters accounting for roughly two-thirds of the total energy used by American manufacturers. Anywhere combustion has to happen, oxygen is a must. In some cases, standard atmospheric air is good enough, but in many industrial combustion applications where high heat is a must, pure oxygen is injected in place of or in addition to air. In the steel industry, for instance, oxygen gas is a key input used to make furnaces run more efficiently, decarburize steel, and more. Oxygen can also be used in glass melting furnaces to reach the same temperatures while consuming less fuel and lowering nitrogen oxide emissions by up to 90%. In all industrial combustion applications, obtaining the right fuel-to-air mixture is crucial to achieving consistent, correct temperatures while minimizing fuel waste, making it extremely important that manufacturers be able to measure their air and oxygen flow accurately.

Wastewater Aeration

Wastewater aeration is the process of adding air to water in order to encourage the growth of bacteria, which then eat and break down contaminants, leaving much cleaner water behind. It’s used extensively both in the treatment of industrial wastewater, and the treatment of the municipal water we drink and use in our homes every day. While algae can be used to provide dissolved oxygen to the system in some cases, in most wastewater aeration systems, air or oxygen is injected into the aeration basins either at the surface or through subsurface bubblers. Much like in industrial combustion, air can be used as a cost- effective input, but pure oxygen gas can also be injected to improve the efficiency of bacteria growth and their consumption of unwanted pollutants. In either case, getting oxygen levels in the system just right is key to ensuring happy bacteria and optimal waste reduction.

HVAC

Heating, ventilation, and air conditioning systems are of crucial parts of effectively all commercial environments, as well as our own homes. They’re especially important in industrial settings where potentially harmful substances can get into the air, ranging from contaminants in labs to sawdust in workshops and beyond. But, while maintaining consistent airflow in a house is one thing, maintaining proper ventilation and the flow of clean air, temperature-correct air throughout an office building or industrial facility is an entirely different problem. As a result, large HVAC systems can be extremely complex in design. They can also be extremely wasteful and costly if not operating correctly. Unfortunately, because of the size of the ducting and the length and winding nature of most HVAC systems, measuring the flow of air throughout an entire building to ensure that blowers, fans, louvers, and control systems are all working correctly can be extremely challenging.

Fermenters and Bioreactors

Fermenters and bioreactors are systems used in laboratories to produce organic materials like cells, bacteria, yeast, enzymes, and much more. Bioreactors are used in a variety of applications, ranging from pharmaceuticals to food additives to biofuels to water treatment processes and beyond. Air is needed for culture growth, and pure oxygen is often chosen to speed up the process and increase density. The gas must be dissolved into the medium the culture is being grown in, and the higher the cell density and the faster growing the culture, the more oxygen required. Like most oxygen applications, levels must be carefully measured and monitored to ensure optimal absorption without unnecessary waste.

Measuring Oxygen Flow with a Thermal Mass Flow Meter

With oxygen gas and air so crucial to so many industrial processes, it’s important that users get their distribution right. Improper feed rates in combustion, aeration, and bioreactors result in less efficient processes with poor output and higher costs – a double loss. Improper airflow in HVAC applications doesn’t just lead to higher costs, it can also jeopardize the health of workers – something far more important than money.

In all of these cases, users need a way to measure air and oxygen gas flow that is extremely accurate, highly repeatable, and cost-effective – three traits perfectly describing thermal mass flow meters.

Thermal Mass Flow Meters Ensure Accurate Oxygen and Air Distribution.

Thermal mass flow meters are one of the most accurate ways of measuring air and oxygen flow, generally offering error rates of less than 1% across a meter’s entire operating range. Thermal mass flow meters are also designed specifically to handle a wide range of flow rates, allowing them to maintain their pinpoint accuracy even in applications with lower flows, like HVAC ducting. Their simple design also ensures downtime is kept to an absolute minimum, and accurate measurements can be taken with a degree of consistency and repeatability unmatched by other metering systems.

Thermal Mass Flow Meters Provide Uninterrupted Flow

Ensuring air and oxygen gas flow can be properly measured is crucial, but if the metering equipment interrupts the flow in any meaningful way, the entire process becomes counterproductive. The probes in thermal mass flow meters are extremely low-profile, creating no meaningful resistance and allowing flow to pass by them effectively undisturbed. That makes them perfect for applications like combustion and aeration, where it’s critical to success that flow into the system be as consistent and pinpoint-accurate as possible.

Thermal Mass Flow Meters are Extremely Cost-Effective

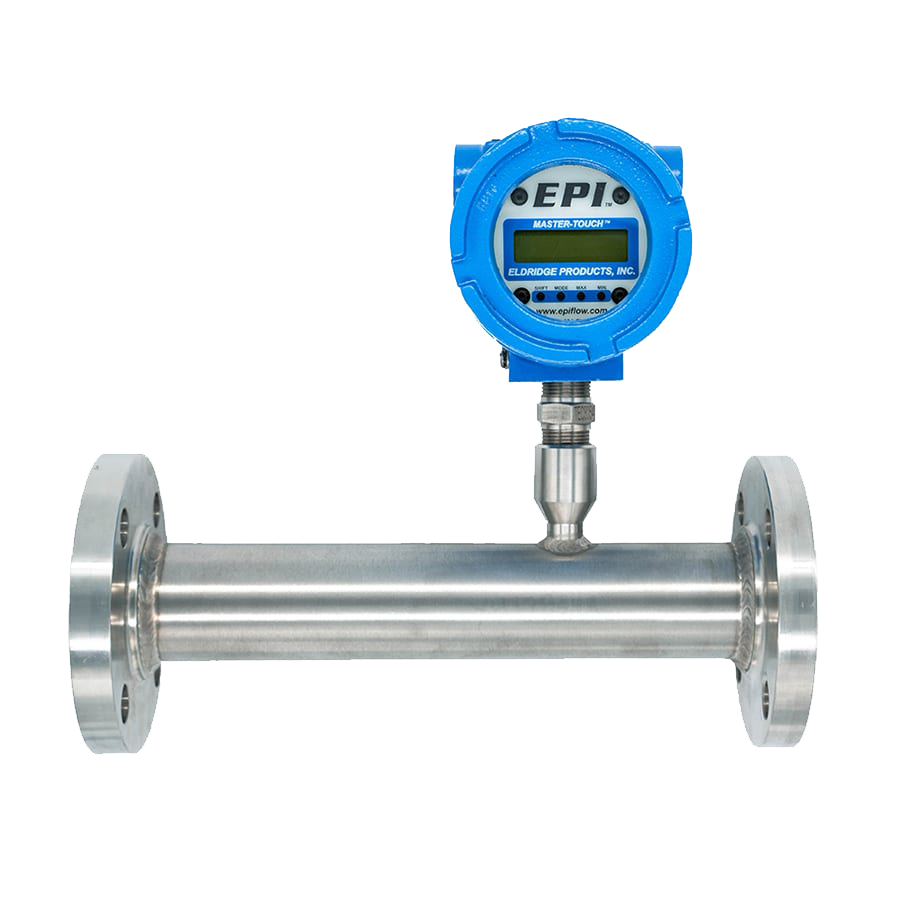

Thermal mass flow meters offer a number of cost benefits based on their ease of installation and their extremely low maintenance requirements. Whether a plant is looking for a permanently fixed inline system or a more temporary insertion style meter, the simple design of thermal mass flow meters allows them to be quickly and easily installed using flanges or threading for inline meters and simple ports for insertion meters. And, because thermal mass flow meters contain no moving parts, they’re exceptionally reliable and require almost no maintenance once installed and operational.

Let EPI Thermal Mass Flow Meters Help You More Accurately Measure Your Air and Oxygen Gas Flows

At Eldridge Products Inc., we’ve been helping our clients accurately measure gas flows for over three decades. Our full line of inline and insertion thermal mass flow meters and easy-to-use control software have been used by thousands of clients around the globe to improve their processes and save money through better measurement and control of their gasses.

If you’re looking for a way to accurately, consistently, and cost-effectively measure your air or oxygen gas flow, we’d love to show you why an EPI Thermal Mass Flow Meter is the ideal tool for the job. Reach out to a member of the EPI team today to find out more!