Methane Gas Measurement with Thermal Mass Flow Meters

Methane is a greenhouse gas that is emitted naturally from a number of sources, including wetlands, the oceans, the breakdown of organic materials like human and animal waste, wildfires, and more. Methane is also a key gas used in commercial and industrial applications. On average, it makes up 94% of the natural gas used to power industry and our homes, and it’s also key in everything from chemical production to advanced rocket fuels.

Unfortunately, in addition to its usefulness as an industrial input, methane is also extremely good at capturing heat, and it’s a direct contributor to the greenhouse effect driving climate change. So, while we need methane, we also need to carefully control how we use it and vent it. The following is a quick primer on how methane gas is used, how it makes its way back into the atmosphere, and how it can be accurately measured and controlled to maximize profitability and minimize environmental impact.

Commercial Uses for Methane Gas

Methane, both in its pure form and as the primary component of natural gas, is an important industrial input, with a variety of uses covering everything from running machinery to sending cargo into space. Because of its widespread use and importance to industry, it’s extremely important for companies using methane in their processes to closely monitor its movement to maximize safety, minimize profit-draining waste, and ensure frictionless production.

Natural Gas

Natural gas – composed of 90% methane or more – is an extremely common fuel which is burned in a variety of commercial and industrial applications, including industrial furnaces, driers, heaters, and generators. Natural gas is also burned to run generator turbines, and is responsible for 40% of utility- scale electricity production across the United States.

Chemical Manufacturing

Methane is used to produce a variety of chemicals that are important to both industry and everyday life. Methane-rich natural gas is a primary input in the process of steam reforming, which uses the reaction between methane’s hydrocarbons and water to create hydrogen. Hydrogen is in turn used as a fuel source and as an input in chemicals like ammonia and hydrochloric acid. Methane is also used to produce methanol, the non-drinkable alcohol used in a variety of solvents and everyday products like antifreeze.

Rocket Fuel

Methane is now being used as a key component in rocket fuel, most notably in the SpaceX Raptor engine which powers Starship, the company’s reusable super-heavy launch system. Methane as a rocket fuel offers two major benefits: its low cost allows for more economical launches, and its clean burning prevents waste deposits from building up inside the engine – an important factor for reusable systems like Raptor. Those qualities, combined with the strides being made in efficiency, could make methane one of the most important inputs in future space travel.

Controlling Methane as a Byproduct

Methane is a greenhouse gas and, as such, it can have a big impact on the atmosphere and the warming of our planet. So, while methane itself is not directly harmful to living things, its environmental effects are. Unsurprisingly, many companies work hard to monitor and minimize their methane emissions, andsweeping new regulations have been proposed to significantly limit the amount of methane emitted from oil and gas production – one of the largest sources of natural gas emissions. However, the natural gas that is a byproduct of oil and gas production is just one of the many sources of methane being vented into the atmosphere every day by commercial and industrial activities. Everything from our water, to our garbage, to our food contributes, making the careful monitoring and, when possible, capture and reuse of methane crucial to our planet’s long-term health.

Agricultural Methane

Agriculture is the world’s second-largest producer of methane emissions, topped only by the gas released naturally by wetlands. Many people have heard the anecdote that “cow farts” are one of the major contributors to global warming (it turns out their burps are worse), but there is a great deal of truth behind the humor, as livestock waste is a top source of agricultural methane emissions. Production of certain foods like rice and the wastage common in food production are also major contributors. All that methane being produced is referred to as biogas, and farmers have become wise to its value as a fuel source. Today, capturing biogas is becoming big business, and the ability to measure its release is of key importance.

Landfill Gas

Municipal landfills contain an enormous amount of organic material, and as that material breaks down, it releases a gas composed of 50% carbon dioxide and 50% methane. With the amount of garbage being dumped in landfills across the country each day, it’s no surprise that municipal landfill gas accounts for 15% of total methane emissions in the United States. Landfills are responsible for carefully tracking and reporting their methane emissions under EPA rule 40 CFR Part 98, which can be a challenge due to the extremely low flow of gas passively emitted from waste breakdown. Much like the methane resulting from agricultural activity, landfill gas can also be redirected, captured, and burned, turning a problem into a potential opportunity.

Anaerobic Digester Gas

Anaerobic digesters use bacteria to break down organic matter in a low oxygen environment, creating methane as a byproduct. They’re used in agricultural settings, but they’re also emerging as a way to improve wastewater treatment systems and recapture energy from our water. From food scraps to grease to fertilizer runoff and more, an enormous amount of organic waste ends up in our water supply. Traditionally, that waste is filtered out and turned into sludge, which must then be disposed of. Today, only a small fraction of the country’s 16,000 treatment plants use anaerobic digesters, but their ability to redirect sludge from landfills and incinerators and recapture useful methane as a fuel source all but guarantees anaerobic digestion will become common in the future, creating a greater need to carefully monitor and redirect biogas emerging from the systems.

Monitoring Methane Flow with a Thermal Mass Flow Meter

Whether controlling venting and emissions, recapturing energy, or feeding industrial processes, the key to profitable, environmentally conscious methane management is good flow measurement. Only by maintaining an accurate picture of the flow within a system can users ensure that fuel mixtures are correct, leaks are detected, inefficiencies are pinpointed, processes run optimally, and the amount of methane vented into the atmosphere is kept to a minimum.

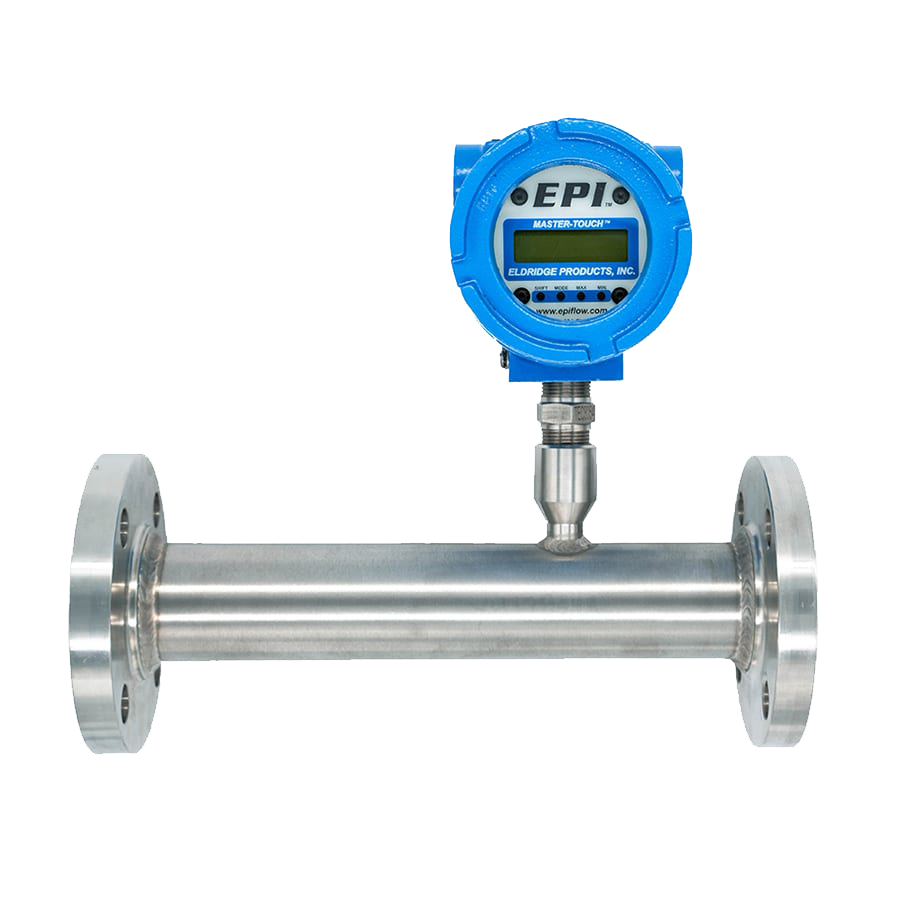

Thermal mass flow meters are tools designed specifically to enable better measurement and management of methane and other gasses. They measure gas flow by detecting heat changes across the system, and offer a level of accuracy, simplicity, and affordability that other types of flow metering can’t match.

Extreme Accuracy

Thermal mass flow meters offer the accuracy, repeatability, and reliability necessary to measure methane gas flow across all industrial, commercial, and municipal applications. With accuracy often within 1% across their full operating range, thermal mass flow meters are perfect for environmental regulation compliance that requires consistent, accurate reporting. They also make it easy to maintain ideal feed rates and detect leaks to ensure maximum safety and profitability in industrial environments.

Low-Flow Capabilities

Thermal mass flow meters enable methane flow measurement across a variety of flow rates. Their ability to accurately and repeatably measure even very low flow rates makes them ideally suited for challenging environments like landfills, where emissions are slow and diffuse.

Negligent Impact on Overall Pressure

Both inline and insertion thermal mass flow meters can accurately measure methane gas flow while having a near-zero impact on system pressure. As a result, thermal mass flow meters can be used even in applications where very specific pressures and flow rates need to be maintained without interruption, like industrial combustion.

Ease of Installation and Minimal Maintenance

Thermal mass flow meters can be easily installed, either inline as permanent fixtures or as retrofitted insertions in pipes and ducting. Because they contain no moving parts, thermal mass flow meters are also extremely reliable, offering very low downtime and minimal maintenance requirements. Those two factors make thermal mass flow meters the most economical way of accurately and repeatably measuring methane gas flow.

Contact EPI Today About Our Methane Thermal Mass Flow Meters

Eldridge Products Inc. is a leading manufacturer of thermal mass flow meters designed to enable the accurate measurement of gasses in industrial and environmental applications, including methane gas. To find out more about our full line of inline and insertion thermal mass flow meters and how they can help your plant improve your flow metering, click here to reach out to a member of the EPI team today.